See what I did there? You’re welcome.

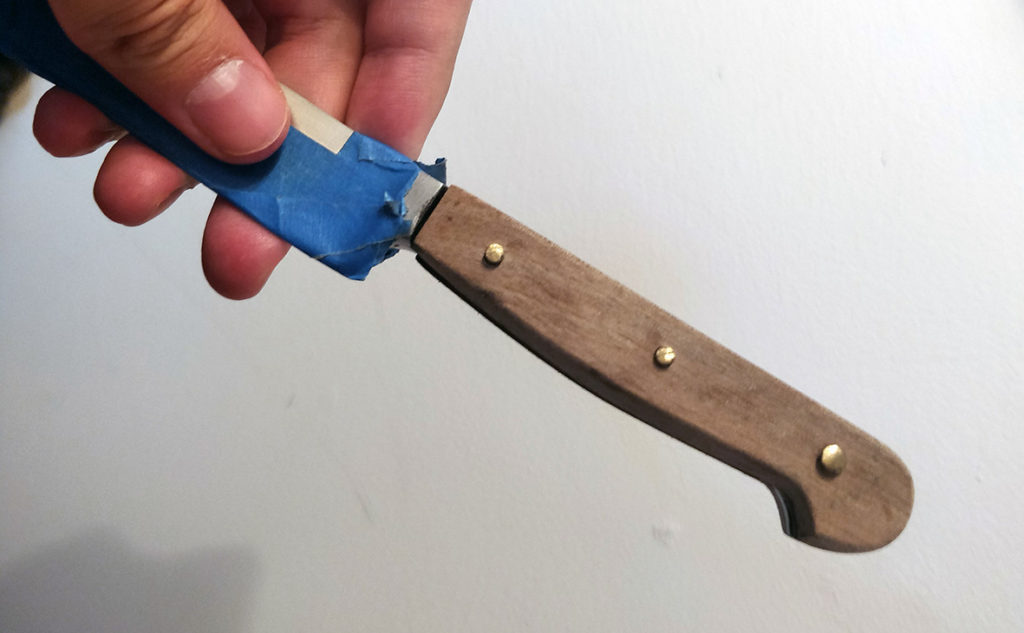

The handle on one of my mother’s kitchen knives was deteriorating so I decided to “fix” it.

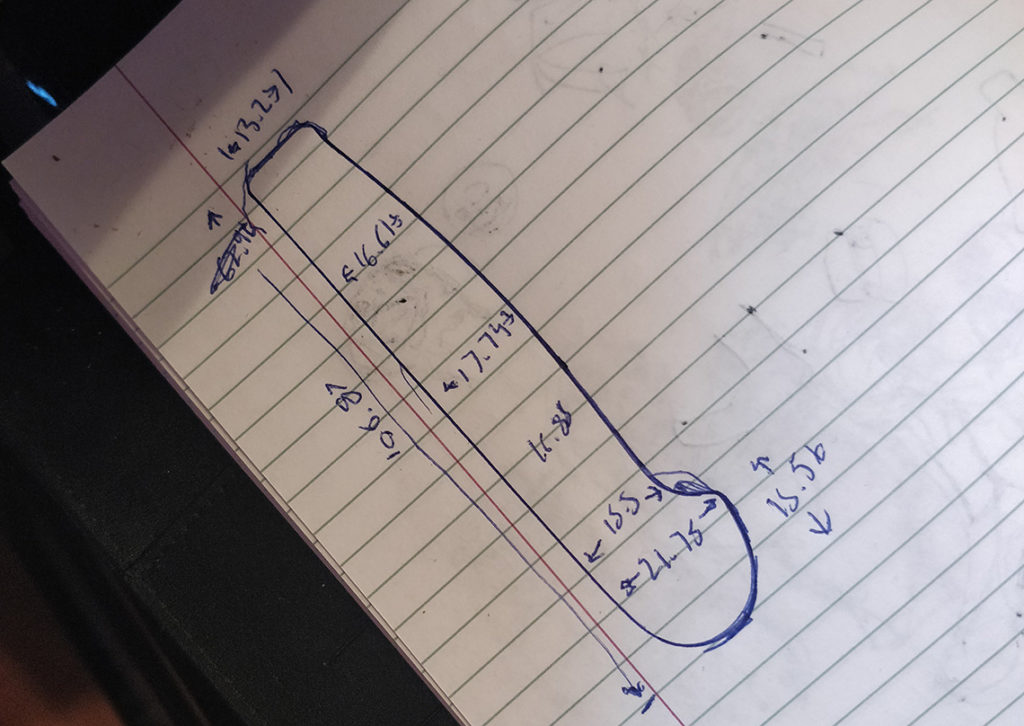

So I took some measurements…

And using those measurements I made a 3D model in Fusion 360.

Which I printed a bunch of times on my SnapMaker 2.0! With adjustments here and there until I was satisfied with the fit.

Once I was happy with the model, I CNCed it out, also using my SnapMaker 2.0, on a piece of test wood. Yeah it does CNC and 3D printing, so what? (Also laser cutting.)

They the test CNCing went pretty well, so I did it again – but this time from using some black walnut from a tree that grew on her childhood home.

Then I cut the brass rods down to size with a hacksaw, and started peening them. Oh also, I glued them in (and the scales to tang) with some resin.

It turned out pretty alright, I think! I did some sanding and used some wood filler to plug a gap, which… I should have used a different colour, but I happened to have one on-hand.

Also I made a quick leather sleeve for it because I started to feel embarrassed by the painters tape.