Have you ever fallen asleep with your kindle in your hand, only to be shocked awake when it clatters to the floor? No? Well, me neither, but I’m given to understand that it’s something that happens to certain people with some regularity.

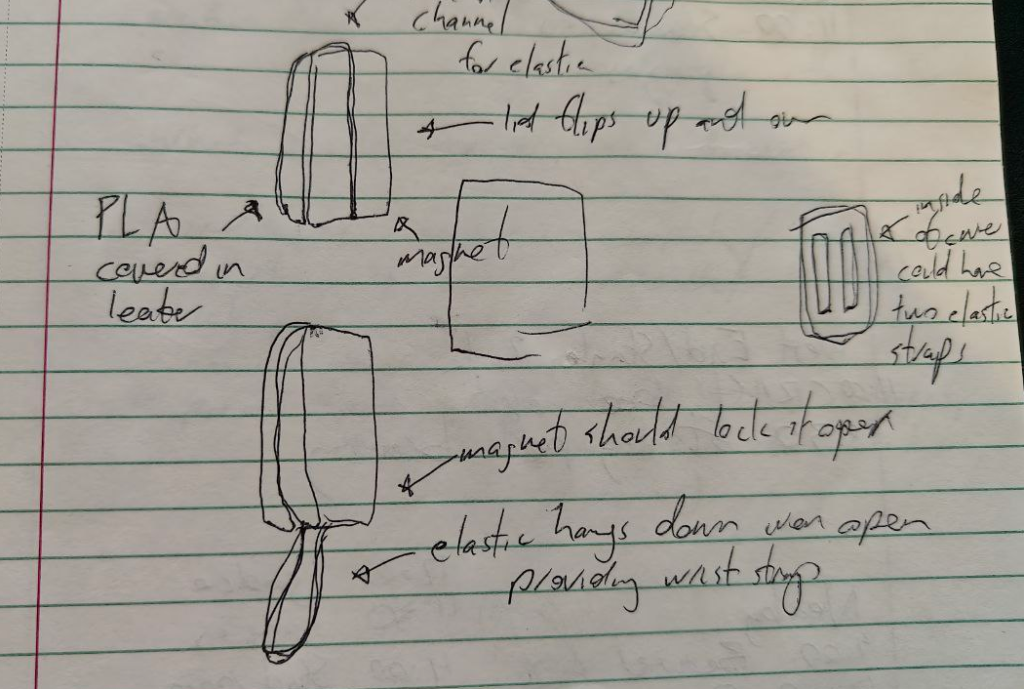

So I got to thinking, and thinking always leads to drawing up some professional-quality diagrams. Wait. Schematics. Yeah, schematics. That sounds fancier.

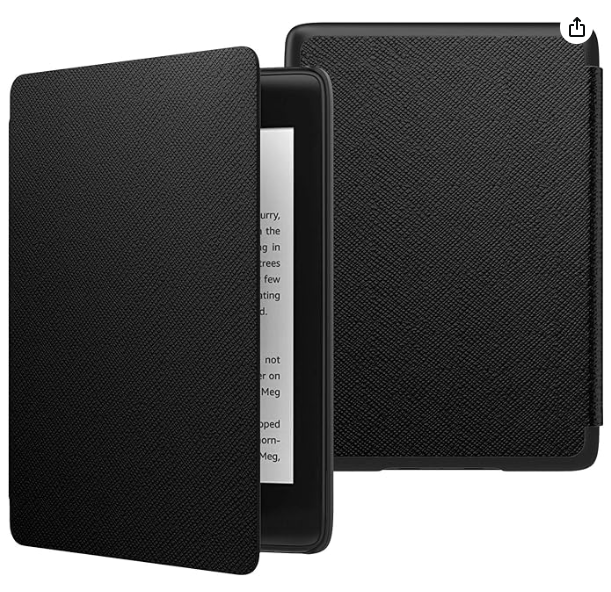

I considered 3D printing the part that connects to the Kindle, but worried it would be too brittle and eventually settled on ordering a very basic case from Amazon.

As I’m sure you immediately noticed, the cover flap hinges from the side, while the schematics very clearly require it to hinge from the top. So I broke out the trusty exacto knife and soon it hinged from nowhere at all.

The next step, as per the schematics, was to add the hand-straps to the back of the flap. So, you know, I kind of did that. Not well, but… I mean they’re there.

Then I attached the safety line, for, you know, safety.

And I placed magnets in both sides to hold it together when it’s open. I should have formed a channel with them (this was the original plan), but instead I didn’t do that and the end product is all the worse for it. It’s all tradeoffs, you know?

But there was no way to know if it would work…

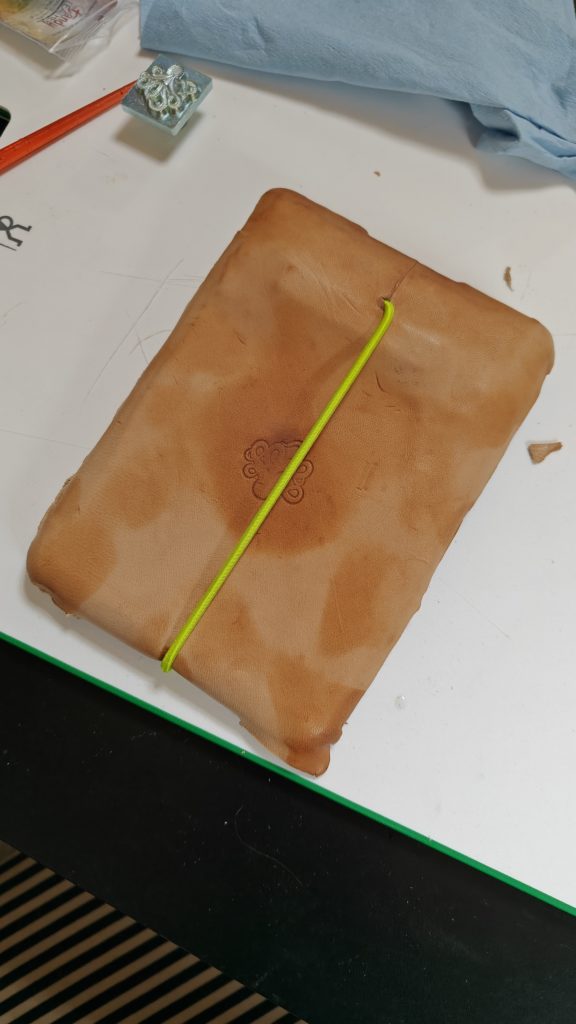

I know it looks awkward, and believe me, it is, but my hand is also larger than necessary. This is what we in the engineering game call “something about tolerances”. Also, please note that I am not, in fact, an engineer. However, as I’m sure engineers often say: it was good enough. Except, I guess, for the painter’s tape forming the hinge. That certainly wasn’t going to hold up, so I did a very bad job wrapping the whole thing in leather.

And then I also quite a poor job staining it.

And there you have it!

Is it nice? No. Is it functional? No. Okay, I guess it is. Is it safe? Sure, if used correctly.